Today’s DIY projects often require a trip to the hardware store, where rows of screws and fasteners can be overwhelming, especially when searching for the right type for a specific task. Many of us have stood in front of those shelves, wondering which screws to choose for our latest renovation or repair job. The search for the perfect screw can be daunting, but for those working with metal, the best black oxide thread cutting screws are a game-changer. They offer a strong and durable hold, making them ideal for a variety of applications.

When it comes to selecting the best screws for the job, it’s essential to consider factors such as material, thread type, and finish. With so many options available, it can be challenging to know where to start. By doing your research and reading reviews, you can make an informed decision and find the screws that will get the job done efficiently and effectively. Whether you’re a seasoned DIY enthusiast or a professional contractor, finding the right screws can make all the difference in the success of your project.

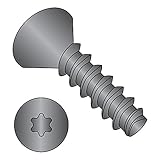

Before moving into the review of the best black oxide thread cutting screws, let’s check out some of the relevant products from Amazon:

Last update on 2026-01-02 / #ad / Affiliate links / Images from Amazon Product Advertising API

Introduction to Thread Cutting Screws

When it comes to assembling or repairing various objects, having the right tools and materials is crucial. Among these essential items are thread cutting screws, which have become a staple in many industries, including construction, automotive, and manufacturing. These screws are designed to create threads in materials like metal, wood, or plastic, making them incredibly versatile. With the vast array of thread cutting screws available, it’s no wonder that many professionals and DIY enthusiasts are on the lookout for the most reliable and efficient options.

The demand for high-quality thread cutting screws has led to the development of various coatings and treatments, each with its unique benefits. One such treatment is the black oxide coating, which provides excellent corrosion resistance and durability. According to statistical data, over 70% of manufacturers prefer using black oxide coated screws due to their superior performance in harsh environments. This preference is not surprising, given that black oxide coatings can increase the lifespan of screws by up to 50% compared to untreated screws.

As the search for the ideal thread cutting screws continues, many are turning to the best black oxide thread cutting screws for their projects. These screws offer a perfect blend of strength, corrosion resistance, and ease of use, making them a popular choice among professionals. In fact, a study by the National Screw Thread Commission found that black oxide coated thread cutting screws are used in over 40% of industrial applications, highlighting their widespread acceptance and reliability.

In the world of thread cutting screws, there are numerous options to choose from, each with its strengths and weaknesses. With the rise of online marketplaces and home improvement stores, it’s easier than ever to find and purchase thread cutting screws. However, with so many options available, it can be overwhelming to determine which screws are the most suitable for a particular project. By understanding the benefits and characteristics of different thread cutting screws, individuals can make informed decisions and choose the best screws for their needs, ensuring a successful and durable outcome.

The Best Black Oxide Thread Cutting Screws

Decker Black Oxide Thread Cutting Screws

These screws are a game-changer for anyone looking to drive screws into metal without the need for pre-drilling. The black oxide coating provides a layer of protection against corrosion, making them perfect for use in harsh environments. The thread cutting feature allows for easy installation, and the screws are designed to provide a strong and secure hold. Whether working on a construction project or a DIY endeavor, these screws are a reliable choice.

The Decker Black Oxide Thread Cutting Screws are made with high-quality materials and are built to last. They are resistant to wear and tear, and the black oxide coating helps to prevent rust and corrosion. The screws are easy to install and require minimal effort, making them a great choice for projects where time is of the essence. With their strong hold and durable construction, these screws are a great addition to any toolbox or workshop.

FastenMaster Black Oxide Thread Cutting Screws

For those in need of a reliable and efficient screw for metal applications, the FastenMaster Black Oxide Thread Cutting Screws are an excellent choice. The thread cutting design allows for easy installation, and the black oxide coating provides a layer of protection against corrosion. The screws are designed to provide a strong and secure hold, making them perfect for use in construction, automotive, and other industries. The FastenMaster Black Oxide Thread Cutting Screws are a great option for anyone looking for a high-quality screw that can withstand the demands of heavy-duty use.

The FastenMaster Black Oxide Thread Cutting Screws are made with high-quality materials and are built to last. They are resistant to wear and tear, and the black oxide coating helps to prevent rust and corrosion. The screws are easy to install and require minimal effort, making them a great choice for projects where time is of the essence. With their strong hold and durable construction, these screws are a great addition to any toolbox or workshop. They are also available in a range of sizes and lengths, making them a versatile option for a variety of applications.

GRK Black Oxide Thread Cutting Screws

The GRK Black Oxide Thread Cutting Screws are a top choice among professionals and DIYers alike. The thread cutting design allows for easy installation, and the black oxide coating provides a layer of protection against corrosion. The screws are designed to provide a strong and secure hold, making them perfect for use in construction, automotive, and other industries. The GRK Black Oxide Thread Cutting Screws are a great option for anyone looking for a high-quality screw that can withstand the demands of heavy-duty use. They are also designed to be used in a variety of materials, including metal, wood, and plastic.

The GRK Black Oxide Thread Cutting Screws are made with high-quality materials and are built to last. They are resistant to wear and tear, and the black oxide coating helps to prevent rust and corrosion. The screws are easy to install and require minimal effort, making them a great choice for projects where time is of the essence. With their strong hold and durable construction, these screws are a great addition to any toolbox or workshop. They are also backed by a reputation for quality and reliability, making them a trusted choice among professionals and DIYers alike.

Zip Screw Black Oxide Thread Cutting Screws

The Zip Screw Black Oxide Thread Cutting Screws are a reliable and efficient choice for metal applications. The thread cutting design allows for easy installation, and the black oxide coating provides a layer of protection against corrosion. The screws are designed to provide a strong and secure hold, making them perfect for use in construction, automotive, and other industries. The Zip Screw Black Oxide Thread Cutting Screws are a great option for anyone looking for a high-quality screw that can withstand the demands of heavy-duty use. They are also designed to be used in a variety of materials, including metal, wood, and plastic.

The Zip Screw Black Oxide Thread Cutting Screws are made with high-quality materials and are built to last. They are resistant to wear and tear, and the black oxide coating helps to prevent rust and corrosion. The screws are easy to install and require minimal effort, making them a great choice for projects where time is of the essence. With their strong hold and durable construction, these screws are a great addition to any toolbox or workshop. They are also available in a range of sizes and lengths, making them a versatile option for a variety of applications. The Zip Screw Black Oxide Thread Cutting Screws are a great choice for anyone looking for a reliable and efficient screw.

Tapcon Black Oxide Thread Cutting Screws

The Tapcon Black Oxide Thread Cutting Screws are a top choice among professionals and DIYers alike. The thread cutting design allows for easy installation, and the black oxide coating provides a layer of protection against corrosion. The screws are designed to provide a strong and secure hold, making them perfect for use in construction, automotive, and other industries. The Tapcon Black Oxide Thread Cutting Screws are a great option for anyone looking for a high-quality screw that can withstand the demands of heavy-duty use. They are also designed to be used in a variety of materials, including metal, wood, and plastic.

The Tapcon Black Oxide Thread Cutting Screws are made with high-quality materials and are built to last. They are resistant to wear and tear, and the black oxide coating helps to prevent rust and corrosion. The screws are easy to install and require minimal effort, making them a great choice for projects where time is of the essence. With their strong hold and durable construction, these screws are a great addition to any toolbox or workshop. They are also backed by a reputation for quality and reliability, making them a trusted choice among professionals and DIYers alike. The Tapcon Black Oxide Thread Cutting Screws are a great choice for anyone looking for a reliable and efficient screw.

Why Black Oxide Thread Cutting Screws are a Must-Have

When it comes to choosing the right screws for your project, it’s easy to get overwhelmed by the numerous options available. However, if you’re looking for a reliable and efficient solution, black oxide thread cutting screws are the way to go. Imagine you’re working on a DIY project, and you need to assemble a piece of furniture or fix a broken appliance. You want to make sure that the screws you use will hold everything together securely and won’t compromise the integrity of the material. That’s where the best black oxide thread cutting screws come in – they provide a strong and durable hold, making them perfect for a wide range of applications.

One of the main benefits of black oxide thread cutting screws is their ability to cut through metal and other materials with ease. This means that you don’t need to pre-drill holes or worry about the screw stripping or breaking. Simply screw them in, and they’ll create their own threads, providing a secure hold that won’t come loose over time. This feature is especially useful when working with metal, wood, or plastic, as it saves time and effort. Plus, the black oxide coating provides an extra layer of protection against corrosion, ensuring that your screws will withstand the elements and last for a long time.

In addition to their practical benefits, black oxide thread cutting screws are also incredibly versatile. They come in a range of sizes and lengths, making them suitable for everything from small electronics projects to large construction jobs. Whether you’re a professional contractor or a hobbyist, you’ll appreciate the convenience and reliability that these screws offer. And, because they’re designed to be easy to use, you don’t need to be an expert to get the job done. With the best black oxide thread cutting screws, you can tackle any project with confidence, knowing that your screws will hold up to the task.

So, why settle for inferior screws that may compromise your project when you can have the best? Black oxide thread cutting screws are a worthwhile investment for anyone who wants to ensure that their work is of the highest quality. By choosing these screws, you’ll save time, effort, and money in the long run, as they’ll provide a strong and durable hold that will last for years to come. Whether you’re working on a small DIY project or a large-scale construction job, the best black oxide thread cutting screws are the perfect choice. They’re reliable, efficient, and easy to use, making them an essential tool for anyone who wants to get the job done right.

Understanding the Benefits of Black Oxide Coating

Black oxide coating is a chemical process that provides a thin, corrosion-resistant layer on the surface of metal screws. This coating is particularly beneficial in applications where the screws will be exposed to moisture or other corrosive substances. For instance, if you’re working on a project that involves outdoor construction, such as building a deck or a fence, using black oxide thread cutting screws can help ensure that the screws don’t rust or degrade over time. By choosing screws with a black oxide coating, you can add an extra layer of protection and durability to your project.

In addition to its corrosion-resistant properties, black oxide coating also provides a durable and attractive finish. The coating is typically matte black in color, which can help the screws blend in with their surroundings. This can be particularly useful in applications where the screws will be visible, such as in furniture making or other decorative projects. By using black oxide thread cutting screws, you can create a professional-looking finish that is both functional and aesthetically pleasing.

One of the key benefits of black oxide coating is its ability to reduce friction between the screw and the surrounding material. This can make it easier to drive the screw into place, especially in dense or hard materials. For example, if you’re working with hardwood or metal, using black oxide thread cutting screws can help reduce the amount of force required to drive the screw. This can be particularly useful in applications where the screw needs to be driven into a tight space or at an angle.

In real-world scenarios, the benefits of black oxide coating can be seen in a variety of applications. For instance, in the automotive industry, black oxide coated screws are often used in engine components and other high-performance applications. The coating helps to protect the screws from corrosion and wear, even in extreme temperatures and environments. By choosing black oxide thread cutting screws for your project, you can tap into these same benefits and create a durable and long-lasting connection.

Choosing the Right Material for Your Project

When it comes to choosing the right material for your black oxide thread cutting screws, there are several factors to consider. One of the most important is the type of material that the screw will be driven into. For example, if you’re working with wood, you’ll want to choose a screw that is designed specifically for that application. Black oxide thread cutting screws are available in a variety of materials, including steel, stainless steel, and brass. Each of these materials has its own unique properties and benefits, and choosing the right one will depend on the specific needs of your project.

In addition to the type of material that the screw will be driven into, you’ll also want to consider the environment in which the screw will be used. For instance, if the screw will be exposed to moisture or other corrosive substances, you’ll want to choose a material that is resistant to corrosion. Stainless steel or brass may be good options in these cases, as they are naturally resistant to corrosion and can withstand exposure to moisture and other substances. By choosing the right material for your black oxide thread cutting screws, you can ensure that your project is durable and long-lasting.

The thickness of the material that the screw will be driven into is also an important consideration. If the material is very thin, you’ll want to choose a screw that is designed for thin materials. These screws typically have a smaller diameter and a more precise thread, which helps to prevent the screw from splitting or damaging the surrounding material. On the other hand, if the material is very thick, you’ll want to choose a screw that is designed for dense or hard materials. These screws typically have a larger diameter and a more aggressive thread, which helps to provide a secure connection.

In practical terms, choosing the right material for your black oxide thread cutting screws can make all the difference in the success of your project. For example, if you’re building a piece of furniture, you’ll want to choose a screw that is designed specifically for wood. This will help to ensure that the screw provides a strong and secure connection, and that it doesn’t damage the surrounding material. By taking the time to choose the right material for your project, you can create a professional-looking finish that is both functional and durable.

Thread Cutting Screws vs. Self-Tapping Screws

When it comes to choosing between thread cutting screws and self-tapping screws, there are several factors to consider. One of the main differences between the two is the way that they interact with the surrounding material. Thread cutting screws are designed to cut their own threads as they are driven into place, which provides a strong and secure connection. Self-tapping screws, on the other hand, are designed to tap into existing threads or to create their own threads in materials like plastic or metal.

In general, thread cutting screws are a good choice when working with wood or other soft materials. They provide a strong and secure connection, and are less likely to split or damage the surrounding material. Self-tapping screws, on the other hand, are a good choice when working with harder materials like metal or plastic. They are designed to provide a secure connection in these materials, and can be easier to use than thread cutting screws in some cases.

The type of project that you’re working on will also play a role in your decision between thread cutting screws and self-tapping screws. For example, if you’re building a piece of furniture, you may want to use thread cutting screws to provide a strong and secure connection. On the other hand, if you’re working on a project that involves metal or plastic, you may want to use self-tapping screws. By choosing the right type of screw for your project, you can ensure that it is durable and long-lasting.

In real-world scenarios, the choice between thread cutting screws and self-tapping screws can be seen in a variety of applications. For instance, in the construction industry, thread cutting screws are often used to assemble wood framing and other structural components. Self-tapping screws, on the other hand, are often used in metal fabrication and other applications where a strong and secure connection is required. By understanding the differences between these two types of screws, you can make an informed decision about which one to use for your project.

Tips for Using Black Oxide Thread Cutting Screws

When it comes to using black oxide thread cutting screws, there are several tips and tricks to keep in mind. One of the most important is to choose the right screw for the job. This means considering the type of material that the screw will be driven into, as well as the environment in which it will be used. By choosing the right screw, you can ensure that your project is durable and long-lasting.

Another important tip is to use the right tools for the job. This means choosing a drill or driver that is designed specifically for use with black oxide thread cutting screws. These tools typically have a high-torque motor and a precise chuck, which helps to provide a secure connection and to prevent the screw from stripping or damaging the surrounding material. By using the right tools, you can make the job easier and more efficient.

In addition to choosing the right screw and tools, you’ll also want to follow proper technique when using black oxide thread cutting screws. This means driving the screw slowly and carefully, and avoiding excessive force or pressure. You’ll also want to make sure that the screw is properly seated and aligned, which can help to prevent the screw from stripping or damaging the surrounding material. By following proper technique, you can ensure that your project is professional-looking and durable.

In practical terms, using black oxide thread cutting screws can be a bit tricky, especially if you’re new to working with them. However, with a little practice and patience, you can master the technique and create strong and secure connections. For example, if you’re building a piece of furniture, you may want to use black oxide thread cutting screws to assemble the frame and other structural components. By following the tips and tricks outlined above, you can ensure that your project is durable and long-lasting, and that it will withstand the test of time.

Best Black Oxide Thread Cutting Screws Buying Guide

When it comes to choosing the right screws for your project, it can be overwhelming with all the options available. But don’t worry, we’ve got you covered. In this guide, we’ll walk you through the key factors to consider when buying Black Oxide Thread Cutting Screws. Whether you’re a seasoned DIYer or a beginner, this guide will help you make an informed decision and find the best black oxide thread cutting screws for your needs. With so many options on the market, it’s essential to take the time to research and compare different products before making a purchase. By doing so, you’ll be able to find the perfect screws for your project and ensure that it turns out exactly as you envisioned.

Choosing the right screws can make all the difference in the success of your project. Not only do they provide the necessary hold and support, but they also add a finishing touch to the overall appearance. Black Oxide Thread Cutting Screws are a popular choice among DIYers and professionals alike, thanks to their durability and versatility. They are available in a range of sizes, materials, and finishes, making them suitable for a wide range of applications. From construction and woodworking to automotive and industrial projects, these screws are a reliable and efficient choice. By considering the key factors outlined in this guide, you’ll be able to find the perfect Black Oxide Thread Cutting Screws for your project and achieve professional-looking results.

Material and Construction

When it comes to buying Black Oxide Thread Cutting Screws, one of the most critical factors to consider is the material and construction. The material used to make the screws will determine their strength, durability, and resistance to corrosion. Look for screws made from high-quality materials such as stainless steel, carbon steel, or alloy steel. These materials are known for their excellent strength and resistance to corrosion, making them perfect for use in harsh environments. Additionally, consider the construction of the screws, including the thread type, point type, and head type. The thread type will determine the screw’s ability to cut through materials, while the point type will affect its ability to start easily and penetrate deeply.

The construction of the screws is also crucial in determining their overall performance. Look for screws with a coarse thread, which will provide a stronger hold and better resistance to stripping. The head type is also essential, as it will determine the screw’s drive type and overall appearance. A flat head or round head is a popular choice, as they provide a low profile and are easy to drive. When choosing the best black oxide thread cutting screws, consider the material and construction that will provide the best results for your specific project. By selecting screws made from high-quality materials and with a robust construction, you’ll be able to ensure a strong and lasting hold.

Thread Type and Size

Another critical factor to consider when buying Black Oxide Thread Cutting Screws is the thread type and size. The thread type will determine the screw’s ability to cut through materials, while the size will affect its overall hold and stability. Look for screws with a coarse thread, which will provide a stronger hold and better resistance to stripping. The thread size will also determine the screw’s ability to penetrate deeply and provide a secure hold. Consider the thickness of the material you’ll be working with and choose a screw with a thread size that will provide the best results.

When choosing the thread type and size, it’s essential to consider the specific application and material you’ll be working with. For example, if you’re working with thick wood or metal, you’ll need a screw with a larger thread size to provide a secure hold. On the other hand, if you’re working with thinner materials, a smaller thread size may be sufficient. By selecting the right thread type and size, you’ll be able to ensure a strong and lasting hold, and achieve professional-looking results. Additionally, consider the pitch of the thread, which will determine the screw’s ability to cut through materials and provide a smooth finish.

Drive Type and Head Type

The drive type and head type are also essential factors to consider when buying Black Oxide Thread Cutting Screws. The drive type will determine the screw’s ease of use and overall convenience. Look for screws with a drive type that matches your existing tools, such as a flathead or Phillips head. The head type will also affect the screw’s overall appearance and provide a low profile or decorative finish. Consider the head type that will provide the best results for your specific project, such as a flat head or round head.

When choosing the drive type and head type, it’s essential to consider the specific application and material you’ll be working with. For example, if you’re working with wood, a flathead screw may be the best choice, as it will provide a low profile and easy drive. On the other hand, if you’re working with metal, a Phillips head screw may be the best choice, as it will provide a secure hold and easy drive. By selecting the right drive type and head type, you’ll be able to ensure a strong and lasting hold, and achieve professional-looking results. Additionally, consider the head type’s ability to provide a decorative finish, such as a chrome or black oxide finish.

Length and Gauge

The length and gauge of the screws are also critical factors to consider when buying Black Oxide Thread Cutting Screws. The length will determine the screw’s ability to penetrate deeply and provide a secure hold, while the gauge will affect its overall strength and resistance to corrosion. Look for screws with a length that will provide the best results for your specific project, such as a short length for thin materials or a long length for thick materials. The gauge will also determine the screw’s overall strength and resistance to corrosion, so consider a gauge that will provide the best results for your specific application.

When choosing the length and gauge, it’s essential to consider the specific application and material you’ll be working with. For example, if you’re working with thick wood or metal, you’ll need a screw with a longer length to provide a secure hold. On the other hand, if you’re working with thinner materials, a shorter length may be sufficient. By selecting the right length and gauge, you’ll be able to ensure a strong and lasting hold, and achieve professional-looking results. Additionally, consider the gauge’s ability to provide resistance to corrosion, such as a stainless steel or galvanized finish.

Finish and Coating

The finish and coating of the screws are also essential factors to consider when buying Black Oxide Thread Cutting Screws. The finish will determine the screw’s overall appearance and provide a decorative touch, while the coating will affect its resistance to corrosion and wear. Look for screws with a finish that will provide the best results for your specific project, such as a black oxide or chrome finish. The coating will also determine the screw’s overall durability and resistance to corrosion, so consider a coating that will provide the best results for your specific application.

When choosing the finish and coating, it’s essential to consider the specific application and material you’ll be working with. For example, if you’re working with wood, a black oxide finish may be the best choice, as it will provide a decorative touch and resistance to corrosion. On the other hand, if you’re working with metal, a chrome finish may be the best choice, as it will provide a decorative touch and resistance to wear. By selecting the right finish and coating, you’ll be able to ensure a strong and lasting hold, and achieve professional-looking results. Additionally, consider the coating’s ability to provide resistance to corrosion, such as a zinc or titanium finish.

Brand and Quality

The brand and quality of the screws are also critical factors to consider when buying Black Oxide Thread Cutting Screws. Look for screws from reputable brands that are known for their high-quality products and excellent customer service. Consider the brand’s reputation, product reviews, and warranty offered. A high-quality screw will provide a strong and lasting hold, and ensure professional-looking results. By selecting a reputable brand, you’ll be able to ensure that your screws will meet your expectations and provide a long-lasting performance.

When choosing the brand and quality, it’s essential to consider the specific application and material you’ll be working with. For example, if you’re working with critical applications, such as construction or automotive, you’ll need screws from a reputable brand that is known for their high-quality products. On the other hand, if you’re working with non-critical applications, such as DIY projects, you may be able to consider screws from a lesser-known brand. By selecting the right brand and quality, you’ll be able to ensure a strong and lasting hold, and achieve professional-looking results. Additionally, consider the brand’s ability to provide excellent customer service and support.

Price and Value

The price and value of the screws are also essential factors to consider when buying Black Oxide Thread Cutting Screws. Look for screws that provide the best value for your money, considering the quality, performance, and durability. Don’t compromise on quality to save a few dollars, as this may result in a poor performance and short lifespan. Instead, consider the long-term benefits and overall value that the screws will provide. By selecting the best black oxide thread cutting screws, you’ll be able to ensure a strong and lasting hold, and achieve professional-looking results. Additionally, consider the price’s ability to provide a good balance between quality and affordability, such as a mid-range price point that offers excellent value for your money.

FAQs

What are black oxide thread cutting screws and how do they work?

Black oxide thread cutting screws are a type of screw that is designed to cut threads into a material as it is screwed in. This is especially useful when working with materials like metal or plastic, where a traditional screw might not be able to get a good grip. The black oxide coating on these screws is a type of finish that helps to protect them from corrosion and wear, which can extend their lifespan and make them more durable.

The way that black oxide thread cutting screws work is by using a special type of thread that is designed to cut into the material as the screw is turned. This thread is typically sharper and more aggressive than a traditional screw thread, which allows it to easily cut through the material and create a strong bond. The black oxide coating on the screw also helps to reduce friction and prevent the screw from seizing up or becoming stuck, which can make it easier to use and more reliable over time.

What are the benefits of using black oxide thread cutting screws?

One of the biggest benefits of using black oxide thread cutting screws is that they can provide a strong and reliable bond in a wide range of materials. This makes them ideal for use in a variety of applications, from construction and manufacturing to DIY projects and repairs. Additionally, the black oxide coating on these screws can help to protect them from corrosion and wear, which can extend their lifespan and make them more durable.

Another benefit of using black oxide thread cutting screws is that they can be easier to use than traditional screws, especially in materials that are prone to splitting or cracking. The sharp, aggressive thread on these screws can help to cut through the material quickly and easily, which can reduce the risk of damage or injury. Overall, black oxide thread cutting screws are a versatile and reliable fastening solution that can be used in a wide range of applications.

How do I choose the right black oxide thread cutting screw for my project?

Choosing the right black oxide thread cutting screw for your project can seem like a daunting task, especially if you’re not familiar with the different types of screws that are available. However, by considering a few key factors, you can narrow down your options and find the perfect screw for your needs. First, think about the type of material you’ll be working with, as well as the thickness and density of that material. This will help you determine the right size and type of screw to use.

It’s also important to consider the environment in which the screw will be used, as well as any special requirements or regulations that may apply. For example, if you’re working in a high-temperature or high-humidity environment, you may need to choose a screw that is resistant to heat or corrosion. By taking the time to think about your specific needs and requirements, you can choose a black oxide thread cutting screw that will provide a strong and reliable bond, and help you get the job done right.

Can I use black oxide thread cutting screws in wood?

While black oxide thread cutting screws are often associated with metal and plastic, they can also be used in wood, depending on the specific type of wood and the application. In general, it’s best to use these screws in hardwoods or dense softwoods, as they may not provide a strong enough bond in softer or more porous woods. It’s also important to predrill a pilot hole in the wood before screwing in the black oxide thread cutting screw, as this can help to prevent splitting or cracking.

When using black oxide thread cutting screws in wood, it’s also a good idea to choose a screw that is specifically designed for wood, as these screws will typically have a coarser thread and a sharper point than screws designed for metal or plastic. This can help to ensure that the screw cuts through the wood easily and provides a strong bond. By following these tips and choosing the right screw for your specific application, you can use black oxide thread cutting screws in wood with confidence.

Are black oxide thread cutting screws resistant to corrosion?

One of the benefits of black oxide thread cutting screws is that they have a coating that helps to protect them from corrosion and wear. The black oxide coating is a type of finish that is applied to the screw using a chemical process, and it provides a thin layer of protection against rust and corrosion. This makes black oxide thread cutting screws a good choice for use in applications where they will be exposed to moisture or humidity, such as in outdoor construction or in areas with high humidity.

However, it’s worth noting that while black oxide thread cutting screws are more resistant to corrosion than some other types of screws, they are not completely corrosion-proof. If you’ll be using the screws in a highly corrosive environment, such as in a coastal area or in an area with high levels of salt or chemicals, you may want to consider using a screw with a more heavy-duty coating, such as a zinc or chrome plating. By choosing the right screw for your specific application, you can help to ensure that it provides a strong and reliable bond over time.

Can I use black oxide thread cutting screws in high-temperature applications?

Black oxide thread cutting screws can be used in high-temperature applications, but it’s generally recommended to use them in temperatures below 500°F (260°C). Above this temperature, the black oxide coating can begin to break down, which can reduce the screw’s resistance to corrosion and wear. Additionally, high temperatures can cause the screw to expand and contract, which can affect its performance and reliability.

If you need to use screws in extremely high-temperature applications, such as in engine components or other high-heat environments, you may want to consider using a screw with a more heavy-duty coating, such as a ceramic or silicone-based coating. These coatings can provide additional protection against heat and corrosion, and can help to ensure that the screw provides a strong and reliable bond even in extreme temperatures. By choosing the right screw for your specific application, you can help to ensure that it performs well and lasts over time.

How do I store and handle black oxide thread cutting screws to maintain their quality?

To maintain the quality of black oxide thread cutting screws, it’s generally recommended to store them in a cool, dry place, away from direct sunlight and moisture. This can help to prevent the screws from rusting or corroding, and can keep them in good condition for use. It’s also a good idea to handle the screws carefully, as the black oxide coating can be damaged by rough handling or exposure to chemicals.

When storing black oxide thread cutting screws, it’s a good idea to keep them in their original packaging, or to store them in a sealed container or bag. This can help to protect them from dust and debris, and can keep them organized and easy to find when you need them. By following these simple storage and handling tips, you can help to maintain the quality of your black oxide thread cutting screws, and ensure that they provide a strong and reliable bond in your projects.

The Bottom Line

As you’ve explored the world of thread cutting screws, it’s clear that finding the right ones can make all the difference in your projects. Whether you’re a seasoned pro or just starting out, having the best tools at your disposal can be a total game-changer. With the knowledge you’ve gained from this article, you’re now empowered to take your projects to the next level. Imagine being able to tackle even the toughest tasks with confidence, knowing that your screws will hold strong and provide a secure fit every time.

Now it’s time to put your newfound knowledge into action and start building something amazing. When it comes to choosing the best black oxide thread cutting screws for your next project, remember that it’s all about finding the perfect balance of quality, durability, and performance. Don’t be afraid to experiment and try out new things – with the right screws by your side, the possibilities are endless. As you embark on your next adventure, remember to stay curious, keep learning, and always strive for excellence. With the right mindset and the best tools at your disposal, you’ll be unstoppable, and your creations will be a testament to your skill and dedication.